What do we doOur Services

GRP Fibreglass Repairs

Darwin Composites has carried out numerous repairs on Glass Reinforced Plastic (GRP) parts. Although GRP is tough, like other products it can be damaged and our skill and experience in carrying out these repairs ensures that they last for the duration. We perfect the finish to intensify the strength.

Pattern Manufacturing and GRP Fibreglass Moulding

Here at Darwin Composites, we are experienced in all aspects of pattern manufacturing and GRP fibreglass moulding working from our base in Shrewsbury and UK. Whether for a bespoke one-off product, or for large production runs, we can design, craft and build to meet your exact needs. We follow various fibreglass moulding processes including hand lay-up or spray application using a state of the art fluid proportioning machine, RTM and infusion.

GRP Fibreglass Production Manufacturing

As part of our process, we initially discuss your requirements with you in detail to ensure we have the correct understanding of the overall product to be achieved noting all specific timeframes. Whether you already have a mould available to use or need us to produce one, we will work hard to determine the best process from the start.

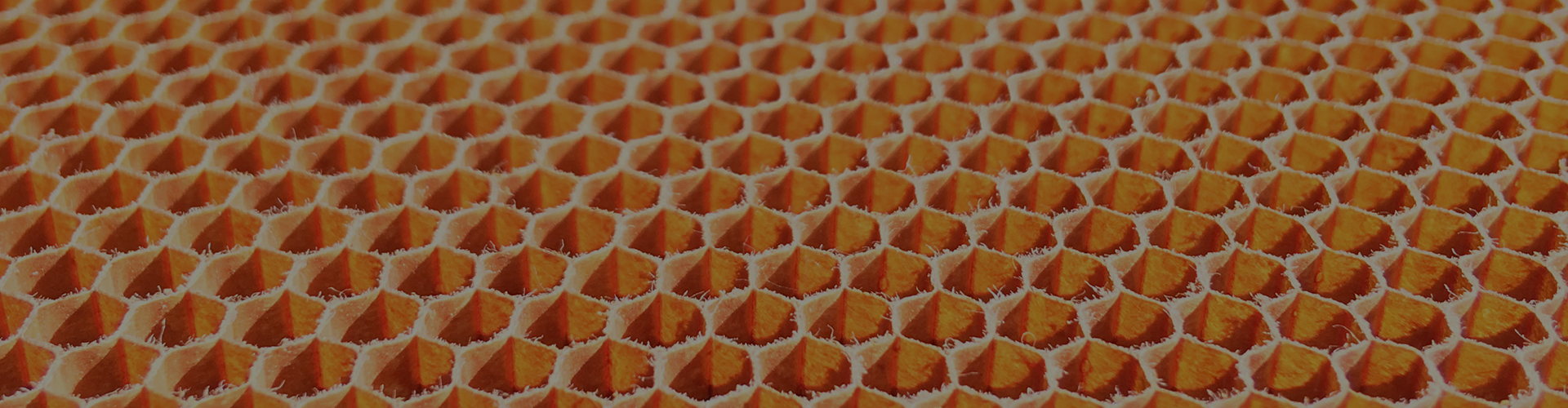

Bespoke Fibreglass Composite Products

Darwin Composites can evolve your ideas into creations using any material from fibreglass, carbon fibre and Kevlar to natural bamboo or woven metal fabrics with bio-resins. Either as modifications to an existing part or moulding a bespoke one-off product, we have the knowledge and experience to ensure complete customer satisfaction.

CNC manufacturing facility's

We offer CNC facilities for your needs. We can evolve your ideas from a sketch to CAD to a CNC component. We offer a fast turnaround with accuracy with both large bed sizes of 1.4m X2.6m. This is ideal for highly accurate pattern and mold manufacturing

Solidworks CAD

SOLIDWORKS 2019 is a proven Design to Manufacturing solution. The software provides the breadth of tools to tackle the most complex problems, and the depth to finish critical detail work. New features help you to improve your product development process to get your innovative products into production faster.